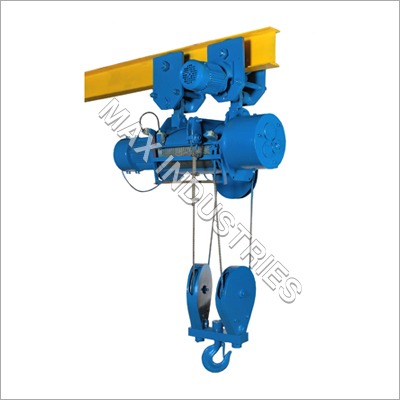

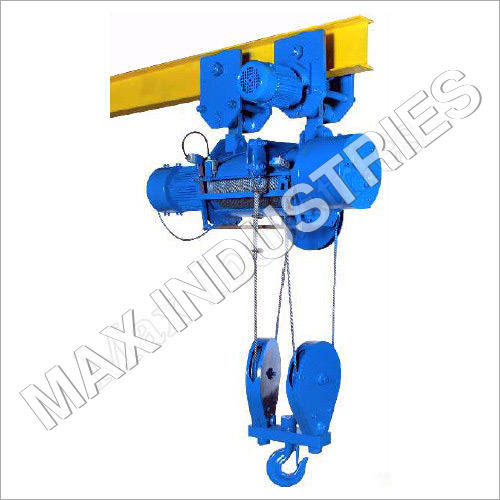

Electric Wire Rope Hoists

Electric Wire Rope Hoists Specification

- Lifting Speed

- 3.58 m/min

- Trolley

- With Motorized Trolley

- Rotation Speed

- 1440 rpm

- Hook

- Forged Steel Hook with Safety Latch

- Frequency

- 50 Hz

- Capacity

- Up to 10 Ton

- Condition

- New

- Lift Speed

- 3.58 m/min

- Max. Lifting Height

- 620 meters

- Max. Lifting Weight

- 10 Ton

- Sling Type

- Wire Rope

- Power Source

- Electric

- Power

- 315 kW

- Voltage

- 380415 V

- Warranty

- Yes

Electric Wire Rope Hoists Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Western Union, Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1-2 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Electric Wire Rope Hoists

Our company is highly acclaimed in global market place for manufacturing and exporting high end quality Electric Wire Rope Hoists. Widely used in industrial manufacturing units, these rope hoists are extensively used for material handling. Wisely manufactured in strict tandem with the industry standards using best quality materials, these Electrical Wire Rope Hoists are offered to clients in varied specifications and capacities for meeting their individual requirements.

Specifications of Electric Wire Rope Hoists:

- Configured & constructed, to give advanced life of the equipment.

- Rope Drums are integrated in the drum housing constructed inline with the side plates load-bearing the Rope Drum. This gives finer strength & small skewing effect to the drum if compared to Long distance bolts. The type N hoists are configured with long distance bolts.

- Standard Construction: Well accessible, designed with - abstracted self-directed units Gearbox (Intermediate), Motor Side (Driving Part), Mechanism Side (Driven Part) & Control Units. These components give ease to the operator.

- Supplied with choices of jam suspension (no travel only hoisting) pull-push system. Geared (hand-operated travel) or electric functioned running of the load.

- Operated by Conical Rotor Motors Z Outset Motors (Make: Anker) for MI-0 Hoist. For different models, Squirrel Cage Induction Motors are enclosed with Electromagnetic Brakes and are accordingly used.

- Factory-made as per IS: 3938 (Indian Regulation) for Class II & Class IV (intermediate duty & heavy duty) utilization.

- Time-tested at 25 % overload.

- Hooks: Hooks are made as per IS: 15560 2005, corroborated on Thrust Bearings.

- Rope Drum: Ready-made with seamless grooves and pipes, are at approx. 2/3rd of the dimension of the wire rope diameter to have comely motion in the drum.

- Rope Guide: Furnishing decorous guide along the line of Rope slides, is easy to pull down from the rope drum while fixing.

- Gears: Made with alloy steel material, incisively machined, gear hobbed & case toughened duly tempered. Spurring / Helical aggregation to furnish strength & smooth-textured operation. Gears are greased with a semi-liquid grease/oil as per the arrangements.

- Specific Hoists with Creep speed arrangement, Higher lifts, Special Control Panel Stations, Short Head rooms all these are also available with customized options and extra cost value.

Technical Details:

| Type | MI-O | MI-1 | MI-II | MI-III | MI-N | MI-IV | |||||||

| Class | II | IV | IV | II | IV | II | II | ||||||

| S.W.L (Tonne) | 0.5 | 1 | 1 | 2 | 2 | 4 | 5 | 3 | 6 | 2 | 10 | 2 | |

| Lift (Mtrs.) | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Apr. Weight (kg.) | 110 | 145 | 270 | 325 | 390 | 510 | 550 | 540 | 830 | 220 | 990 | 220 | |

| Dim. B | 700 | 940 | 1120 | 1315 | 1190 | 1370 | 1370 | 1275 | 1455 | 980 | 1645 | 980 | |

| Dim. C | 500 | 740 | 555 | 771 | 590 | 770 | 770 | 590 | 770 | 380 | 1180 | 380 | |

| Hoisting. Speed mts./min. | 9 | 4.5 | 9 | 4.5 | 8 | 4 | 4 | 8 | 4 | 5 | 2.65 | 5 | |

| Hoisting. Motor H.P (K.W.) | 1.5 | 1.5 | 3 | 3 | 5 | 5 | 5 | 7.5 | 8 | 3 | 7.5 | 3 | |

| Traveling . Motor | 16 | 16 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 12 | 18 | 12 | |

| HP (K.W.) | 0.25 | 0.25 | 0.25 | 0.3 | 0.5 | 0.75 | 0.75 | 0.5 | 0.75 | 0.25 | 0.75 | 0.25 | |

| Min Height Of I beam-mm | 125 | 125 | 185 | 175 | 250 | 250 | 250 | 250 | 250 | 150 | 300 | 150 | |

| F | Min | 75 | 75 | 90 | 90 | 125 | 125 | 125 | 125 | 125 | 80 | 0 | 80 |

| Max | 140 | 140 | 180 | 180 | 210 | 210 | 210 | 210 | 210 | 210 | 0 | 210 | |

| A Headrocm | 710 | 710 | 980 | 1035 | 1160 | 1265 | 1265 | 1260 | 1440 | 860 | 1550 | 860 | |

| D | Min | 310 | 310 | 155 | 155 | 165 | 165 | 165 | 165 | 165 | 135 | 430 | 135 |

| Max | 340 | 340 | 200 | 200 | 180 | 180 | 180 | 180 | 180 | 200 | 470 | 200 | |

| @E | Min | 400 | 400 | 400 | 400 | 415 | 415 | 415 | 415 | 415 | 365 | 435 | 365 |

| Max | 435 | 435 | 445 | 445 | 460 | 460 | 460 | 460 | 490 | 400 | 470 | 400 | |

| G | 26 | 26 | 26 | 34 | 34 | 44 | 44 | 44 | 65 | 34 | 89 | 34 | |

| H | 65 | 65 | 130 | 130 | 155 | 155 | 155 | 175 | 175 | 300 | 85 | 300 | |

| I | 170 | 170 | 150 | 267 | 192 | 303 | 303 | 235 | 375 | 150 | 375 | 150 | |

| J | 195 | 195 | 275 | 310 | 320 | 355 | 355 | 375 | 405 | 270 | 635 | 270 | |

| K | 310 | 310 | 310 | 310 | 310 | 310 | 310 | 310 | 310 | 500 | 310 | ||

| M | --- | --- | 385 | 385 | 385 | 385 | 385 | 385 | 385 | --- | 385 | --- | |

| No. Of Falls | 2 | 4 | 2 | 4 | 2 | 4 | 4 | 2 | 4 | 2 | 6 | 2 | |

Superior Construction and Safety Features

Built from heavy-duty steel and finished with corrosion-resistant paint, these hoists provide outstanding strength and resilience in demanding environments. Integrated overload protection and electromagnetic fail-safe braking systems ensure safe and controlled operations. The forged steel hook with a safety latch adds an extra layer of security during lifting activities.

Flexible Operation and Advanced Technology

Designed for versatility, our wire rope hoists feature both pendant and remote control options, allowing operators to choose their preferred mode. The motorized trolley enables smooth horizontal movement, while the precision gearing supports reliable lift speeds between 3.5 and 8 m/min. The Class F motor insulation and three-phase power supply suit intensive, continuous use.

FAQ's of Electric Wire Rope Hoists:

Q: How can Electric Wire Rope Hoists with medium/heavy duty rating be used in industrial settings?

A: These hoists are ideal for heavy lifting tasks in factories, warehouses, and industrial facilities, efficiently moving loads up to 10 tons with reliable safety and precision, especially where consistent operation is required.Q: What benefits does the electromagnetic fail-safe brake provide?

A: The electromagnetic fail-safe brake enhances operational safety by automatically engaging in the event of a power failure or emergency, preventing accidental load drop and maintaining secure load handling during lifting or suspension.Q: When should I consider using the remote control versus the pendant control for this hoist?

A: Remote control is best for situations requiring operator mobility or when working at a distance from the hoist, while pendant control is suitable for close-proximity, direct control during load handling, based on workflow and safety needs.Q: Where can these electric wire rope hoists be installed?

A: These hoists are suitable for installation in indoor environments such as factories, warehouses, and industrial workshops across India, wherever robust lifting solutions are needed for medium to heavy-duty operations.Q: What is the process for routine maintenance on these hoists?

A: Routine maintenance involves inspecting wire ropes, hooks, gears, and the brake system, ensuring controls function properly, checking insulation for wear, and lubricating moving parts as per manufacturer guidelines to maximize longevity and safety.Q: How does the precision gearing impact hoist operation?

A: Precision helical and spur gears in the hoist mechanism deliver smoother movement, reduced vibration, and greater load stability during lifting, ensuring reliable and energy-efficient performance even at high rotation speeds.Q: What warranty and after-sales service come with these hoists?

A: Each new electric wire rope hoist is backed by a manufacturer's warranty. Support includes technical assistance, spare parts availability, and guidance on installation and maintenance to ensure optimal performance and customer satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Rope Hoist Category

20 Ton Electric Wire Rope Hoist

Price Range 100000.00 - 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Power Source : Electric

Warranty : Yes

Sling Type : Wire Rope

5 Ton Electric Wire Rope Hoist

Price Range 200000.00 - 800000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Power Source : Electric

Warranty : Yes

Sling Type : Wire Rope

Powered Wire Rope Hoist

Price Range 100000.00 - 200000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Power Source : Electric

Warranty : Yes

Sling Type : Wire Rope

Wire Hoist

Condition : New

Power Source : Other, Threephase

Warranty : 1 Year

Sling Type : Wire Rope

|

MAX INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry